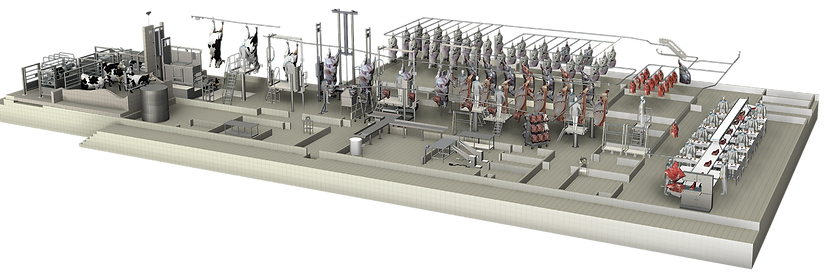

CATTLE SLAUGHTER

Meat Tech Group and its business partner COMMAN have realized modern slaughterhouse and meat processing plant projects that set an example in many regions of the world and contributed greatly to the development of the region. With the cattle slaughterhouses developed in the most suitable qualities for the expectations of the user; offers modern, technological, environmentally friendly and efficient solutions for the correct processing of red meat.

Moreover ;

- Paddock systems

- Cooling, freezing systems

- Blood drying systems etc. supplementary equipment

- Hygiene, lighting, etc. in the enterprise. equipment in the fields

- Floor, wall, ceiling hygienic coating and insulation applications provides its services.

MeatTech Group; offers project design, production, assembly, service and warranty services from a single source. While realizing the highest quality standards in this whole process; It always prioritizes animal welfare, worker safety, ergonomic working conditions, efficiency, longevity, environmental awareness and hygiene. It leads the industry by developing innovative solutions in these areas.

![halal_11 [Dönüştürülmüş].png](https://static.wixstatic.com/media/5546bc_488c8b1d68064f38b078720b41187afc~mv2.png/v1/fill/w_89,h_85,al_c,q_85,usm_0.66_1.00_0.01,enc_avif,quality_auto/halal_11%20%5BD%C3%B6n%C3%BC%C5%9Ft%C3%BCr%C3%BClm%C3%BC%C5%9F%5D.png)

Circular Cutting Cell

Suitable for cattle slaughtering.

Suitable for kosher and halal slaughtering.

Prevents animal’s flutter by compressing.

Designed for reducing animal and butcher accidents.

It is fully automatic and appropriate for halal slaughtering.

The animal is taken in the equipment from the back door and with the help of pistons, the animal is fixed on both sides and at the top.

After the fixation, the animal is turned 180 ̊ or 90 ̊ and slaughtered.

Lift Elevator

It is the elevator that carries out the transfer of the slaughtered cattle to the bleeding and processing lines.

Bleeding Line

It is the line where the animal is kept waiting for the blood to drain after the slaughtering process has taken place. There are large-sized stainless channels and grates on the floor.

Tail Opening Platform

Tail part of the cattle is opened. Anus and esophagus of the cattle is clipped in order to avoid the release of extrement

FOOT and HORN CUTTING The feet and horns are cut using a pair of hydraulic scissors at the end of the bleeding line and before the processing, the processing line starts at the stage platform with a transfer between the rails.

Hydraulic Transfer Unit

With the hydraulic transfer units, the transfer process between the rails is provided.

Units are assembled as double or triple depending on the capacity.

Mono Twinrail Transfer

With the hydraulic transfer units, the transfer process between the rails is provided.

Units are assembled as double or triple depending on the capacity.

Processing Line

It is the line where the transportation between stations takes place during the processes of cattle becoming a carcass.

Dehiding Platform

It is the section where the skinning drum and the moving platforms on both sides are used together.

It enables the butchers to face the skin from top to bottom with the head on the platforms.

Brisket Opening Platform

Facing is the opening of the breast (breast) bone with a specially designed saw without damaging the internal organs.

This process allows the rumen and internal organs to be removed more easily.

Tripe Extracting Platform

The rumen and intestines are removed and lowered onto the automatic rumen inspection band, thanks to the movable and specially designed platform; It passes through the veterinary control point and is automatically (untouched) transported to the offal chambers.

Liver Extracting

The liver is taken by the butcher and transferred to the visceral chamber after passing through the veterinary control point, thanks to the liver-liver conveyor. The head-liver conveyor is suitable for transporting the head and liver to the lower and upper floors as well as going to the rooms on the existing floor.

Carcass Splitting Platform

This station is the part where the carcasses, whose internal organs were removed, are divided into two by using the carcass division saw together with the movable and featured platform.

There are saws suitable for capacities of 50 pcs/day and 500 pcs/day.

The saw prevents cross contamination thanks to its disinfection cabinet.

Veterinary Control Platform

At this station, the carcass, liver, head and tripe of a single animal meet at the same point and pass through the veterinarian control.

The animal, which is diagnosed as suspicious, is separated from the line and directed to the suspect cold room.

Red Meat and Poultry Slaughterhouses and Cold Storage